JOB 522 LAB Multiprocess Inverter Welding Generator

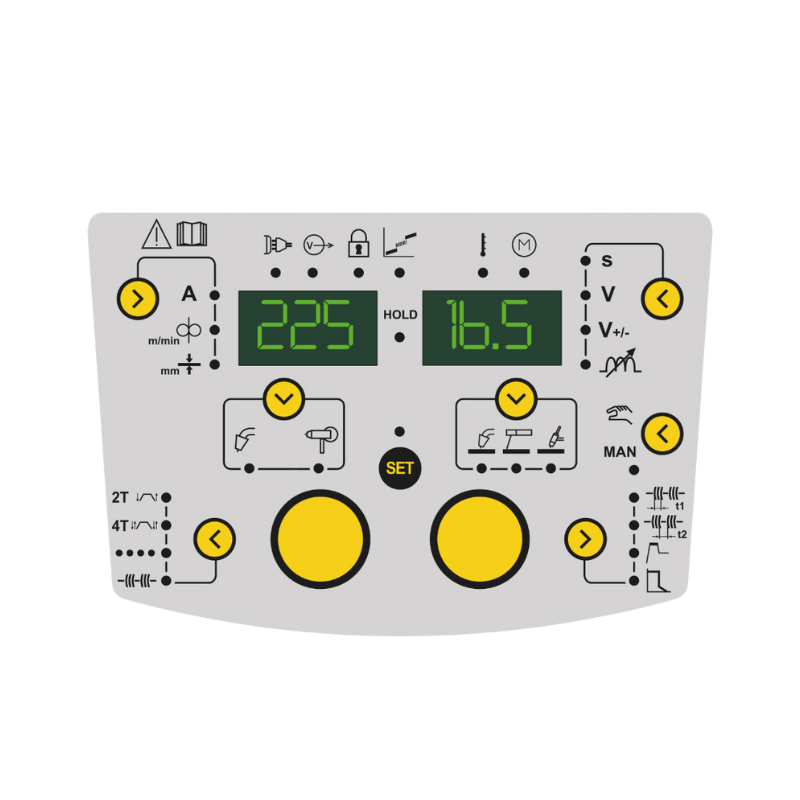

The JOB 522 LAB multiprocess inverter welding generator meets professional and specialist welding needs and is guaranteed by the LAB mark of excellence. It allows welding in Synergic MIG / Manual MIG / WIRE No Gas / MMA / TIG Lift with great precision. Controlling the generator is simple and intuitive while offering all the performance and adjustments of a professional welding machine.

JOB 522 LAB is extremely flexible: in synergic MIG mode, programs for welding many metals and alloys such as steel, stainless steel, aluminum and brazing with copper silicon or copper aluminum wires are preloaded. Through the SD card it is possible to update and add new programs. The microprocessor memory also allows you to save customised programs.

In MMA mode it allows the welding of rutile and basic coated electrodes. TIG Lift mode is perfect for precision work.

- FEATURES

- MIG

- MMA

- TIG

- SPECIFICATIONS

- Single-phase power supply voltage (230 V)

- Delivers 200 A in direct current

- Ammeter / Voltmeter for easy adjustment

| Open circuit voltage | 85V |

| Welding current range | MIG: 10 – 200A MMA: 10 – 160A TIG: 10 – 200A |

| Weight | 30 kg |

| Dimensions | 790mm x 400mm x 790mm |

- Robust 4 roller wire feeder diameter 37 mm.

- Gas test function: to check the operation of the pressure reducer without advancing the wire.

- Wire loading function: to easily load the wire into the torch without gas outlet.

- Coil housing diameter 100 – 200 mm.

- Synergic or manual regulation.

- Preloaded programs for many materials.

- SD Card Reader: to update programs and add new ones.

- Personal program memory.

- Inductance Adjustment: This value can be adjusted to reduce weld spatter.

- Adjustable: Burn Back, Hot Start, Wire approach speed.

- Welding modes: 2T / 4T / spot / stich.

- Predisposition for use of spool gun or potentiometer torches.

- Adjustable Arc Force: to obtain an optimal welding with each electrode it is possible to adjust the temporary increase of the current when the electric arc becomes short.

- Adjustable Hot Start: to obtain an optimal arc ignition with each electrode it is possible to adjust the increase of the initial current.

- Anti-sticking: allows you to easily detach the electrode if it remains glued to the piece.

- TIG LIFT: arc striking occurs by touching the piece with the electrode and slowly lifting it. The risk of contaminating the workpiece with the tungsten electrode is small.

- Automatic Slope up: progressive increase of the welding current to obtain a flawless start of the welding seam.

To request a product, contact us today!

Our team is ready to assist. Give us a call or submit an enquiry via our online contact form.

236 Maddington Rd

Maddington 6109

Western Australia